Heatsink Design-ZZcooler Electronics Company

General Rules for Heat Sink Design

Drive the heat from the component to air within the available volume and temperature difference

Thermal interface material at contacting surfaces

Area and conductivity for conduction and spreading

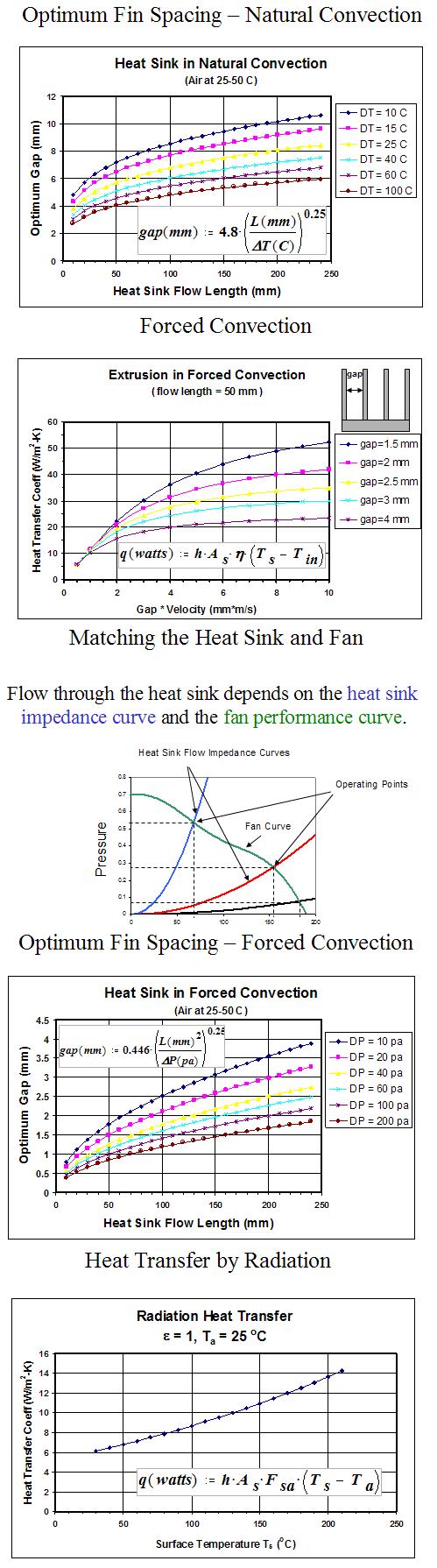

Surface area for convection and radiation

Surface treatment for convection and radiation

At a minimum in raw material cost

Least volume / mass of material

Lowest cost material

At a minimum in manufacturing process cost

Material compatible with versatile, low cost, low waste processes

Easy to prototype, cost effective to mass produce

With robust mechanical retention, easy installation

Heat Sink Design Methods

Heat transfer correlations

Quick back of the envelope calculations

Rough size of heat sink required

Numerical Design Tools ¨C QFIN

Combine correlations with numerical conduction calculations

More robust handling of geometry details, flow bypass, interfaces, ducts, fans ˇ

Comprehensive Design Tools

Icepak CFD software ¨C interface tailored for electronics cooling

Gambit + Fluent CFD software ¨C full capability tools

Selection Criteria & Metrics

Heat Transfer Performance: W/oC/Volume

Fin density required

Type of spreading required

Weight & Cost:

mass/Volume, mass/W;

cost/volume, cost/W

Form factor & shape

Fin aspect ratios ¨C type of fin technology

Distance for heat transport in the x, y, and z directions

Spreading enhancement

Need heat pipes?

How many?

Heat Sink Application Inputs

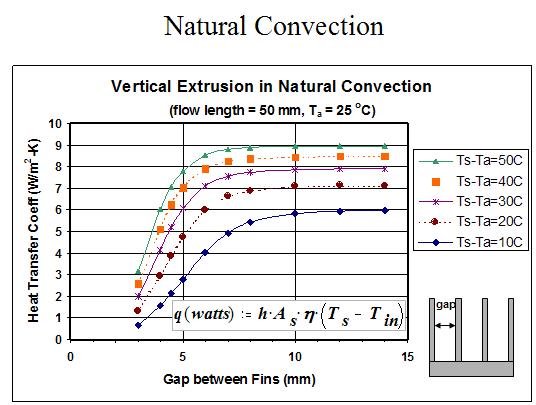

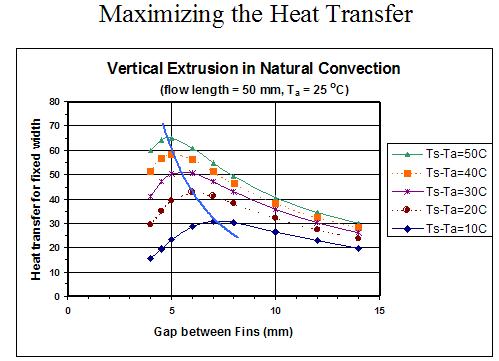

Natural convection

Given heat sink temperature delta above air & length of flow path

Forced convection

Ducted air flow without bypass

Given fan curve ¨C use limits 0.7*CFM_max & 0.4*P_max

Given max flow and pressure ¨C use pressure for design then check if CFM is within limits

Non-ducted air flow with significant bypass

Use 1.3X dynamic head of approach flow as driving pressure

(will need to solve flow bypass network for final design)

Fan-heat sink

Use 0.5*CFM_max and 0.5*P_max

Mass limits (x,y,z are dimensions in meters)

mass < x*y*((z-0.006)*0.25+0.006)*2700 (kg) ¨C extrusion possible

Otherwise will likely need assembled fin technology heat sink

Fin Density Required

x-y is plane of heat sink base, z is normal to base

Check thermal performance requirement

Separate spreading resistance to get ~fin resistance required

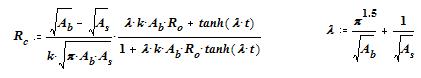

Spreading ¨C from heat source over x-y size & base thickness (Seri Lee Formula)

W/oC/cu. in. of Fin Volume ¨C select fin density (Al Fins)

Below 0.03 ¨C Natural Convection possible

Below 0.20 ¨C Low Density Fins, Low DP (gaps >~ 3 mm)

Below 0.40 ¨C High Density Fins, Low DP (<~20 Pa)

Below 0.65 ¨C High Density Fins, High DP (Blowers)

Above 0.80 ¨C Look for liquid or two-phase radiator type HS

If getting close to each limit, consider next higher option or copper

The above performance limits increase by 15% if weight limits allow copper fins.