散热片一般设计规则

驱动组件内空气的热量可用的体积和温差

接触表面的热界面材料

区和电导率传导和扩散

对流和辐射的面积

表面处理为对流和辐射

在原材料成本最低

最小体积/材料的质量

最低成本的材料

至少在生产过程成本

材料兼容多功能、低成本、低浪费的过程

容易原型、成本有效的大规模生产

强大的机械记忆,安装方便

散热器的设计软件

传热的相关性

快速的信封计算

粗糙的所需散热器的大小

数值设计工具——QFIN

结合相关性和数值传热学计算

更健壮的处理几何细节、流绕过接口、导管、粉丝…

全面的设计工具

Icepak CFD软件,界面为电子冷却

策略+流利的CFD软件——全面能力的工具

选择方法

传热性能:W / oC

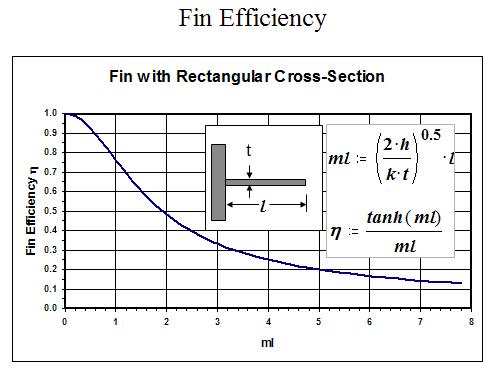

鳍密度要求

所需的传播类型

重量和成本:

质量/体积、质量/ W;

成本/体积,成本/ W

形式和形状

鳍方面比率——鳍技术的类型

热传输的距离x,y,和z方向

传播增强

需要热管道吗

散热器的应用

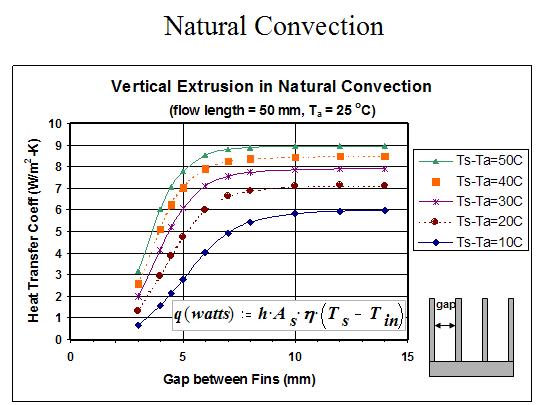

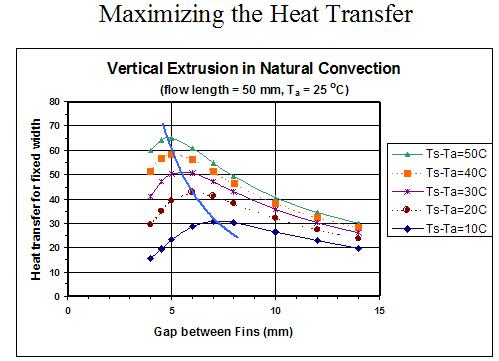

Natural convection

Given heat sink temperature delta above air & length of flow path

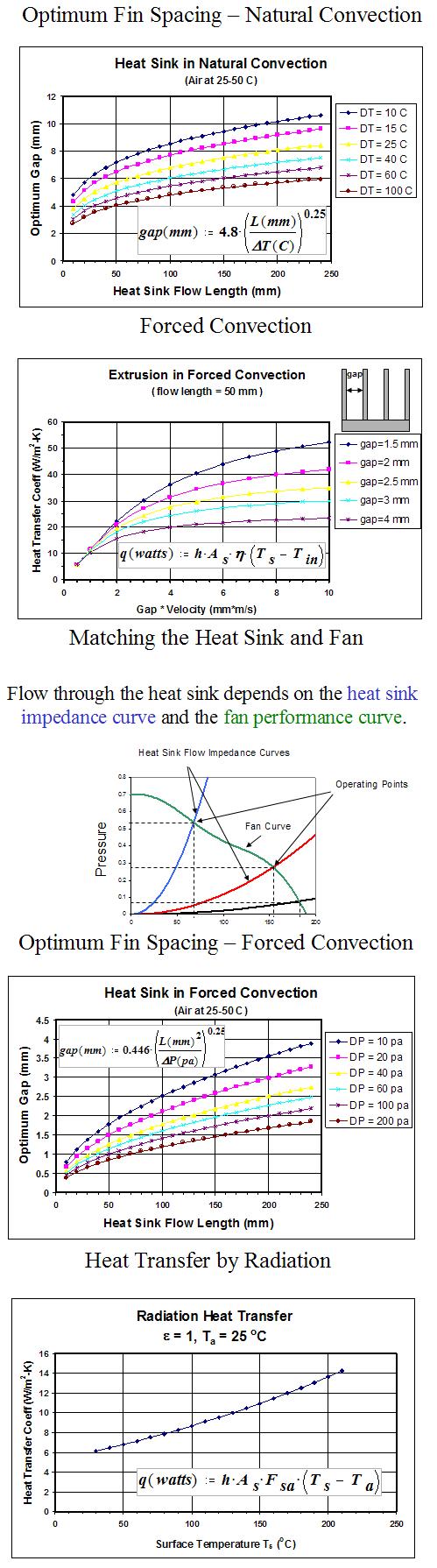

Forced convection

Ducted air flow without bypass

Given fan curve – use limits 0.7*CFM_max & 0.4*P_max

Given max flow and pressure – use pressure for design then check if CFM is within limits

Non-ducted air flow with significant bypass

Use 1.3X dynamic head of approach flow as driving pressure

(will need to solve flow bypass network for final design)

Fan-heat sink

Use 0.5*CFM_max and 0.5*P_max

Mass limits (x,y,z are dimensions in meters)

mass < x*y*((z-0.006)*0.25+0.006)*2700 (kg) – extrusion possible

Otherwise will likely need assembled fin technology heat sink

Fin Density Required

x-y is plane of heat sink base, z is normal to base

Check thermal performance requirement

Separate spreading resistance to get ~fin resistance required

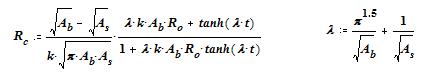

Spreading – from heat source over x-y size & base thickness (Seri Lee Formula)

W/oC/cu. in. of Fin Volume – select fin density (Al Fins)

Below 0.03 – Natural Convection possible

Below 0.20 – Low Density Fins, Low DP (gaps >~ 3 mm)

Below 0.40 – High Density Fins, Low DP (<~20 Pa)

Below 0.65 – High Density Fins, High DP (Blowers)

Above 0.80 – Look for liquid or two-phase radiator type HS

If getting close to each limit, consider next higher option or copper

The above performance limits increase by 15% if weight limits allow copper fins.